When it comes to understanding and troubleshooting the electrical system of your vehicle, having a good grasp of the CDI ignition wiring diagram is essential. The CDI (Capacitor Discharge Ignition) system is responsible for delivering sparks to the spark plugs at the right time, ensuring smooth engine operation. In this article, we will delve into the importance of CDI ignition wiring diagrams and how to effectively use them.

Why CDI Ignition Wiring Diagrams are Essential

CDI ignition wiring diagrams are crucial for several reasons:

- They provide a visual representation of the electrical connections in the ignition system.

- They help in identifying the various components of the CDI system and their respective functions.

- They assist in troubleshooting electrical issues by pinpointing potential problem areas.

How to Read and Interpret CDI Ignition Wiring Diagrams

Reading and interpreting CDI ignition wiring diagrams may seem daunting at first, but with a bit of practice, it becomes easier. Here are some tips to help you navigate through the diagram effectively:

- Start by familiarizing yourself with the key symbols and color codes used in the diagram.

- Follow the flow of the electrical current from the power source to the components to understand the circuit.

- Pay attention to the labels and legends that provide information about each component.

Using CDI Ignition Wiring Diagrams for Troubleshooting

CDI ignition wiring diagrams are invaluable when it comes to troubleshooting electrical problems in your vehicle. Here’s how you can use them effectively:

- Identify the specific area of the electrical system that is malfunctioning.

- Refer to the wiring diagram to trace the connections and locate any faulty components or wiring.

- Use a multimeter to test the continuity and voltage at various points in the circuit.

Importance of Safety

Working with electrical systems can be hazardous if proper safety precautions are not taken. Here are some safety tips to keep in mind:

- Always disconnect the battery before working on any electrical components.

- Use insulated tools to prevent electrical shocks.

- Avoid working on the electrical system in wet or damp conditions.

- If you are unsure about a particular procedure, seek help from a professional mechanic.

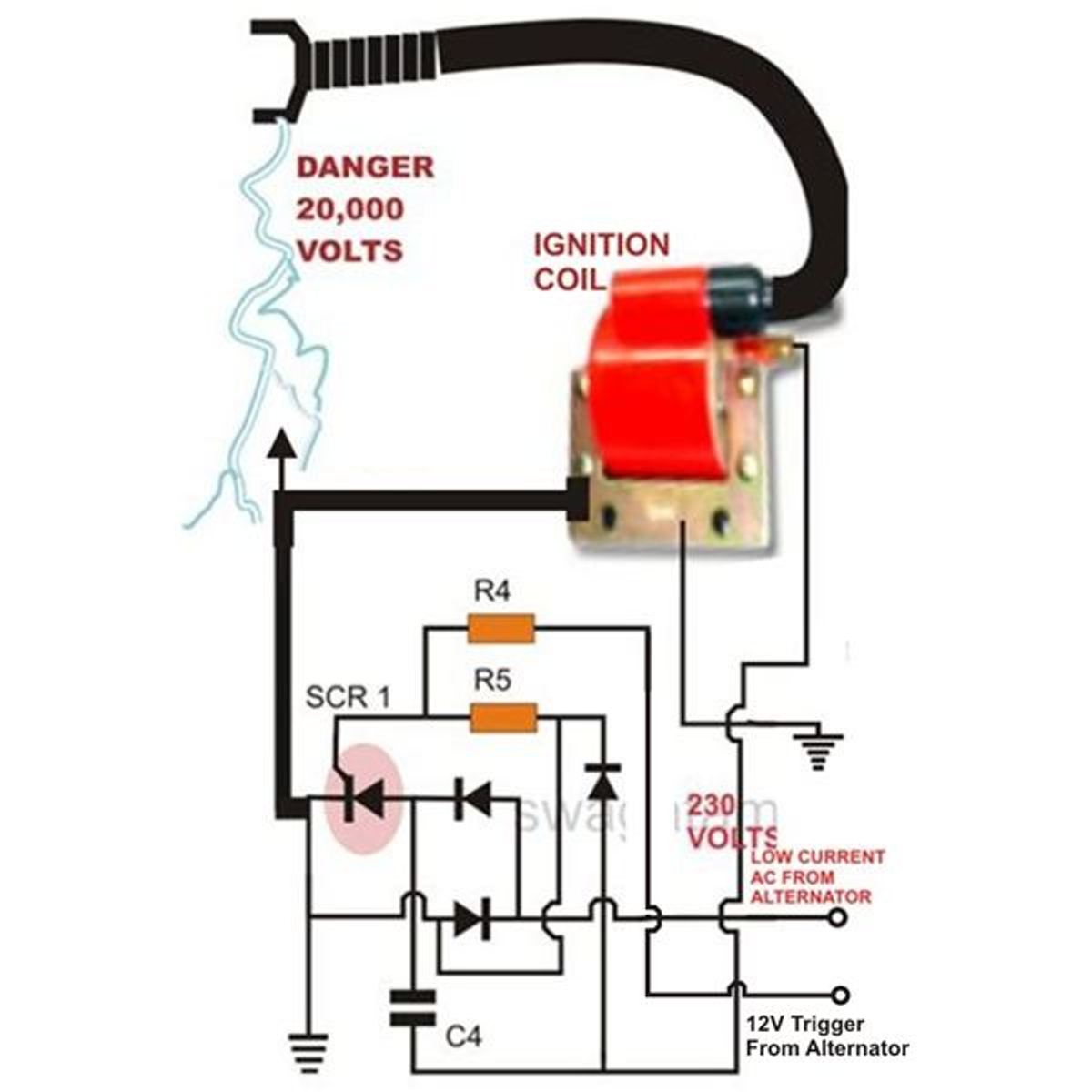

Cdi Ignition Wiring Diagram

Basic Ignition Wiring Diagram With Cdi

How to Make a Capacitive Discharge Ignition (CDI) Circuit for Two

Everything You Need To Know About Yamaha Cdi Ignition Wiring Diagram In

Cdi Ignition Schematic

5 Pin CDI Wiring Diagram (Pictured AND Explained!) – Off-Road Official

Cdi Electronic Ignition Wiring Diagram